PROCESS / COOLING WATER TREATMENT SYSTEM

Technologies / Cooling Water Treatment System

PROCESS / COOLING WATER TREATMENT SYSTEM

SEAWATER TREATMENT FOR COOLING/PROCESS AT OFFSHORE / COASTAL INDUSTRIES

INDUSTRIAL PROCESS WATER OR COOLING WATER

Water is considered as a raw material in industrial processes. When water is a raw material, it has to strictly meet the requirements due to the concerned process in terms of purity, salinity, microbiological presence, pathogens, solids, turbidity, undesirable salts. WATER provides a good environment for harmful microbes to grow and causes biological fouling and corrosion in water and reduces the efficiency of the condensers used for cooling or process in refining of oil/gas products, specialty chemicals (petrochemical refineries), power plant and other process industries.

Biofouling caused by mussels and algae restricts the intake to firewater and jockey pumps at offshore facilities using seawater for their firewater systems. Shock dosing of sodium hypochlorite at set intervals to the firewater pump caisson and a continuous dosing of sodium hypochlorite to the jockey pump caisson, makes the firewater pump caissons / firewater main loop clean and free from macrofouling (algae free).

ELECTROCHEMICAL DISINFECTION & TREATMENT OF PROCESS / COOLING WATER

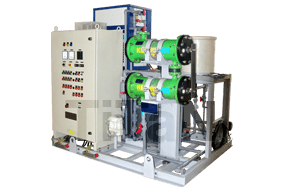

To prevent the growth of microorganisms, algae and biofilms Noble Eco System® offers the state of art RT CHLOR®-S Series onsite sodium hypochlorite generator (chlorine generator systems) for treating the process water or cooling water and fire water streams to meet the industrial (process) challenges.

RT CHLOR®-S SYSTEM incorporates Noble Eco System’s state of art bipolar KLOROGEN® / KLOROGEN®-S parallel plate electrolyzer or Hypopac® concentric tubular bipolar electrolyzer for generating free radicals and chlorine as Hypochlorite. Noble Eco System’s electrolyzer design incorporates free removal of hydrogen and also prevents scaling due to its ingenious design. These self cleaning design ensures near maintenance free operation without any acid cleaning, ensuring the microorganisms, algae growth prevention and performs consistently for years together.

RT AME CHLOR ALKALI PLANT

Benefits

- Onsite Safe & effective disinfectant generation

- Easy to install, operate and service

- Automatic & Instant Operation System

- Self Cleaning Electrolyzer design

- Eliminates Hazardous material storage

- Corrosion Proof Electrolyzers

- Modular Construction, Skid or Containerized Systems

- Improved Heat Exchanger Efficiency & avoids break downs

Application

- Oil Rigs & Platforms process water

- Oil Refineries Process water

- Mining Industries Process water

- Offshore Process water treatment

- Power Plant cooling water treatment

- Petrochemical cooling water treatment

- Boiler Feed Water Treatment System

- Industries Using Fire Water Systems

- Coolers Water Treatment System

- HVAC Water Treatment System